Offshorewinches

Intelligent winch solutions enabling maximum workability

Overview

Turn-key offshore winch solutions featuring advanced motion control technology

Seatools is unique in its ability to provide a wide range of both standardized and customized offshore winch solutions featuring advanced motion control technology. A rarely found combination of expertise in hydraulic and electric drive technology, motion control technology, and offshore and subsea electronics results in mission-critical AHC / CT hoisting and umbilical winches with outstanding reliability and workability levels, irrespective of encountered conditions. In order to guarantee performance in the field and minimize commissioning times we make use of advanced simulations during the development of our winch solutions. These simulations enable us to verify controller performance and pre-program the controller’s most optimal settings ahead of commissioning.

However, our offering extends beyond the delivery of marine winch solutions. We take a step forward in unburdening our clients by delivering additional (drive train) components and sub-systems, such as umbilical terminations, (subsea) HPUs, actuators, etc… Doing so benefits quality and lead times, but also improves cost-effectiveness and shifts the burden of project management away from our clients.

- Scope

-

- AHC / CT hoisting winches

- AHC / CT umbilical winches

- Equipment rental and sales

- Value creation

-

- Tailored to your requirements

- Thoroughly tested and fail-safe winch controllers

- Short lead and commissioning times

- Track record

-

- AHC / CT rental fleet

- 1.8 MW umbilical winch – Van Oord

- Numerous ROV & trencher AHC / CT winches

By offering both custom and standard winches for sale and rent, our engineers propose a solution suitable for every technical requirement, lead time, and budget. Learn more?

OUR OFFERINGS

- AHC / CT hoisting winches

- AHC / CT umbilical winches

Controlled handling of loads under adverse conditions

Seatools offers a wide range of standardized and customized AHC (active heave compensated) and CT (constant tension) hoisting winches that allow for continuous operations under harsh environmental conditions. In order to improve workability and minimize commissioning times, winch controllers are extensively simulated.

Key features:

• Full service offering

• Rental and sales solutions

• Short lead and commissioning times

Mission critical umbilical winches for uninterrupted offshore operations

The umbilical winch, responsible for the transfer of power and data between the vessel and the operable subsea equipment, plays a crucial role in the operational uptime of an entire offshore operation as it inevitably represents a single point of failure. Seatools, with its vast experience and capabilities in subsea infrastructure mounted on mission-critical equipment, houses all resources needed to design and deliver fully customized AHC and CT umbilical winches. Also capable of delivering additional drive train sub-systems (e.g. umbilical termination, SHPU, etc.), clients can outsource full-fledged projects to a single supplier, which benefits quality levels and lead time while unburdening the client.

HOW WE CREATE VALUE

-

Tailored to your requirements

By offering both customized and standardized AHC / CT umbilical and hoisting winches, in addition to equipment sales and rental possibilities, we match every need, technical requirement, admissible lead time, and available budget.

-

Thoroughly tested and fail-safe winch controllers

Thanks to our best-in-class simulations we deliver first-time-right solutions and fail-safe winch (control) systems. Before an AHC winch is installed on site, its control system is extensively simulated. As such, we predict the controller’s response to any condition ahead of installation, and implement the most effective control strategy. Moreover, as early as the design stage our simulations facilitate analysis of system component defects, such as a failing motion sensor. We guarantee our systems feature sufficient fault tolerance levels.

-

Short lead and commissioning times

Also when it comes to lead and commissioning times our simulation capabilities make the difference. Simulations enable us to pre-program the controller’s most optimal settings ahead of commissioning. In addition, Seatools relies on an extensive experience base and control algorithm library. In practice, this means our lead times are short and expensive offshore commissioning time is reduced.

We simulate our AHC winch control systems upfront in order to guarantee industry-leading workability levels and minimize commissioning times. Want to know more?

TRACK RECORD

A trustworthy track record

- Project duration:

- 10 months

- Client

-

1.8 MW CT umbilical winch

In order to power its new subsea trencher “Deep Dig It,” van Oord approached Seatools for the design and delivery of a CT umbilical winch. The result was a plug-and-play containerized umbilical winch that stands out in its ability to transfer exceptionally large amounts of power and data: a total of 1800 kW of power at a voltage rating of 4100 VAC. To guarantee uninterrupted operations across a wide variety of (environmental) conditions, much effort was invested in heat management during the engineering phase.

- Client

-

AHC winch for dual-mode ROV

The ROHP II is a multipurpose inspection ROV that performs a wide variety of inspection and intervention tasks. The ROV comes with two operational modes: a hanging mode and a free-flying mode.

The deployment system of the ROV comprises a containerized winch that, in combination with a series of sheaves and a hydraulic cylinder, features AHC functionality. In order to allow for the free-flying mode, the ROV itself had an integrated tether winch.

- Project duration:

- 5 months

- Client

-

Constant tension ROV winch

In 2009, Seatools completed this high-precision fall-pipe ROV system for Jan de Nul. The system’s ingenious design facilitates easy transportation and enables its use on various of our clients’ vessels.

Along with the ROV, Seatools delivered a 7 kN ROV constant tension (CT) winch that includes the umbilical and umbilical termination. When in CT mode, the winch will spool in and out as required so as to follow the ROV’s motion relative to the vessel, while keeping the umbilical tension constant.

- Project duration:

- 7 months

- Client

-

25 kN CT umbilical reeler

The Arthopod 600 is a subsea pipeline trencher that can be deployed for both pre- and post-lay subsea trenching. For this project, Seatools developed an innovative subsea pipeline trenching technique that efficiently digs large trenches in hard soils.

In order to transfer all electrical current and fiber signals from the control container to the Arthropod 600, Seatools delivered a plug-and-play CT reeler. As with all Seatools winches, the reeler came as a plug-and-play unit that included a spooling device, power distribution and controls, umbilical, slip ring unit, and umbilical termination.

- Project duration:

- 3 months

- Client

-

Integrated CT winch

Seatools developed a dedicated Remotely Operated Cleaning Machine (ROCM) to clean a 400-meter-long power plant’s cooling water intakes. In order to power the vehicle and to transfer data between the control room and the vehicle, the crawler featured an integrated umbilical winch that was fitted at the rear of the crawler. The constant torque control system of the winch ensured a nearly constant tension in the umbilical during movement of the crawler.

- Project duration:

- 5 months

- Client

-

CT Umbilical winch-towed trencher

The Jetting Bull is one of the first towed subsea cable trenchers ever built – a truly pioneering project in the field of subsea cable trenching at its time of completion. Still today, the machine features a very effective design because of its tubular frame’s dual functionality. Not only does the frame transfer the towing forces, it also transports jetting water to the jetting fingers. In addition to the subsea trencher, Seatools also delivered the umbilical drum winch with constant tension (CT) functionality.

In order to guarantee performance in the field and minimize commissioning times we make use of advanced simulations during the development of our winch solutions.

Multimedia

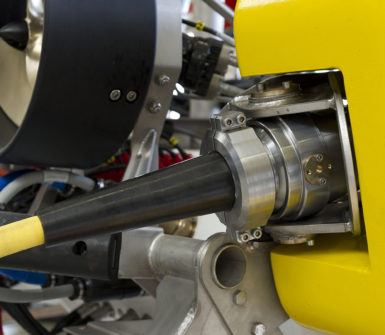

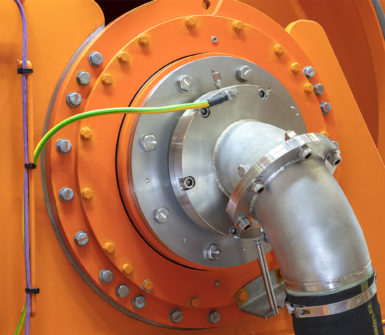

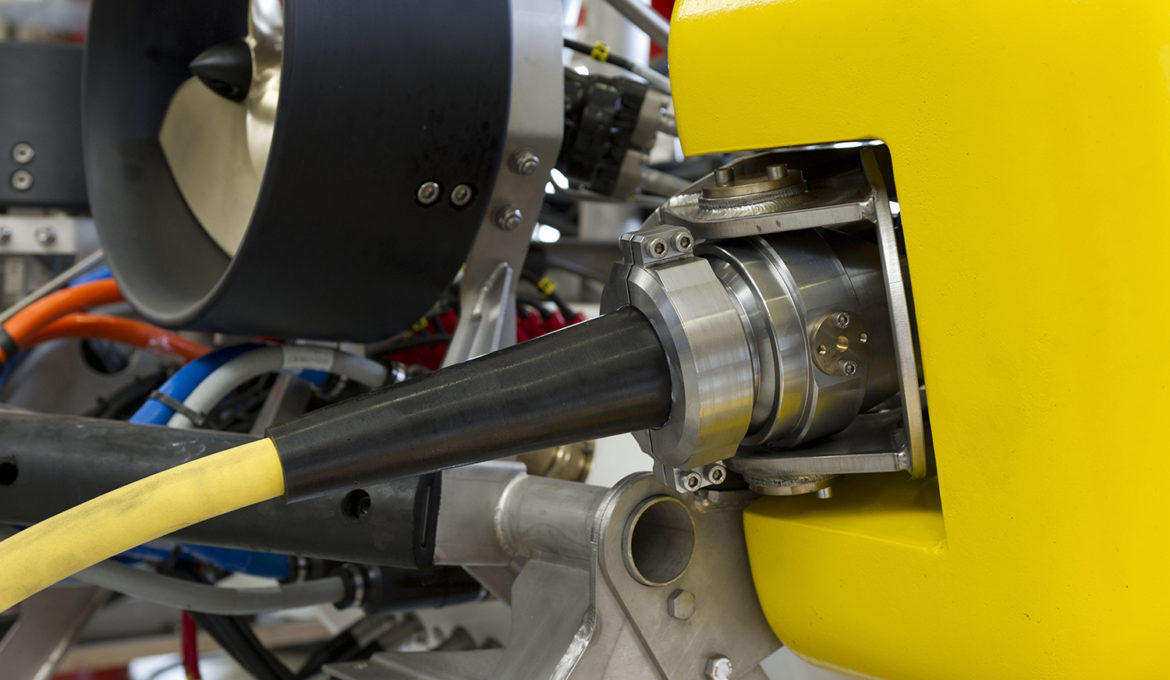

Our specialist knowledge of drive train components such as umbilical terminations have proven to be of great value to our customers. In particular, our electrical engineering department is capable of terminating fiber optics and performing FO verification measurements. Because our capabilities reach beyond the winch system itself, we unburden our clients, eliminate interface risks, improve overall quality, and reduce overall cost and lead time

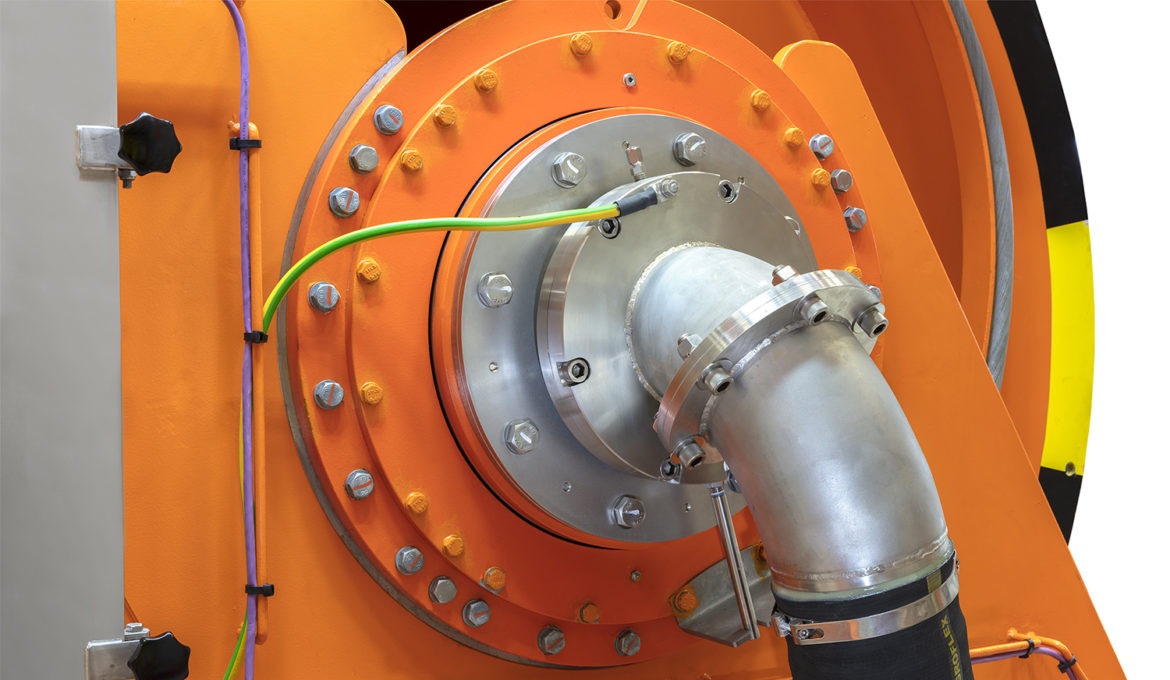

Slip ring units have a profound influence on the (long-term) reliability of the overall winch system. The high power density, high voltages, and rotating movement makes it a delicate component that requires specialist knowledge to guarantee proper procurement, installation, and maintenance. Seatools has an extensive track record in the field of high-voltage and high-amperage slip ring units, deployed in mission-critical umbilical winch systems.

CONTACT

WOULD YOU LIKE TO DISCUSS YOUR PROJECT WITH OUR EXPERTS?

CONTACT FORM

OTHER CHANNELS

- General

- +31 (0) 186 68 00 00

- info@seatools.com

- Sales

- +31 (0) 186 68 00 00

- sales@seatools.com

- Service (outside office hours, emergency only)

- +31 (0)186 65 00 75