DipMate® Pro – Backhoe dredgingmonitoring & control system

Monitoring and control system for precision backhoe dredging

Overview

Monitoring and control for maximum backhoe dredging performance in the toughest of environments

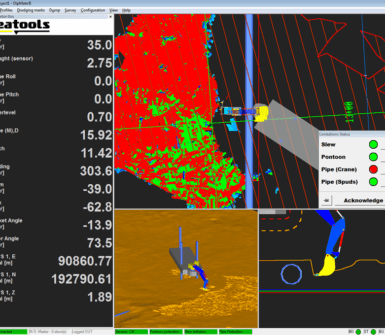

The DipMate® Pro is an ultra-reliable backhoe dredging monitoring and control system for accurate visualization, registration, and controlling of backhoe dredging operations. With 60+ DipMate systems active in the field, DipMate® is the backhoe dredging monitoring and control system of choice for operators around the world. An achievement that is largely attributed to 16 years of field feedback processed in an ever-more capable system. As a result, the system contains a well-developed and operator-friendly MMI, including all available functionalities for effective backhoe dredger monitoring.

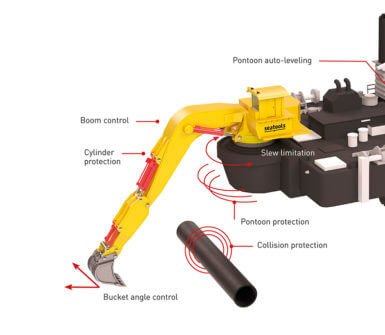

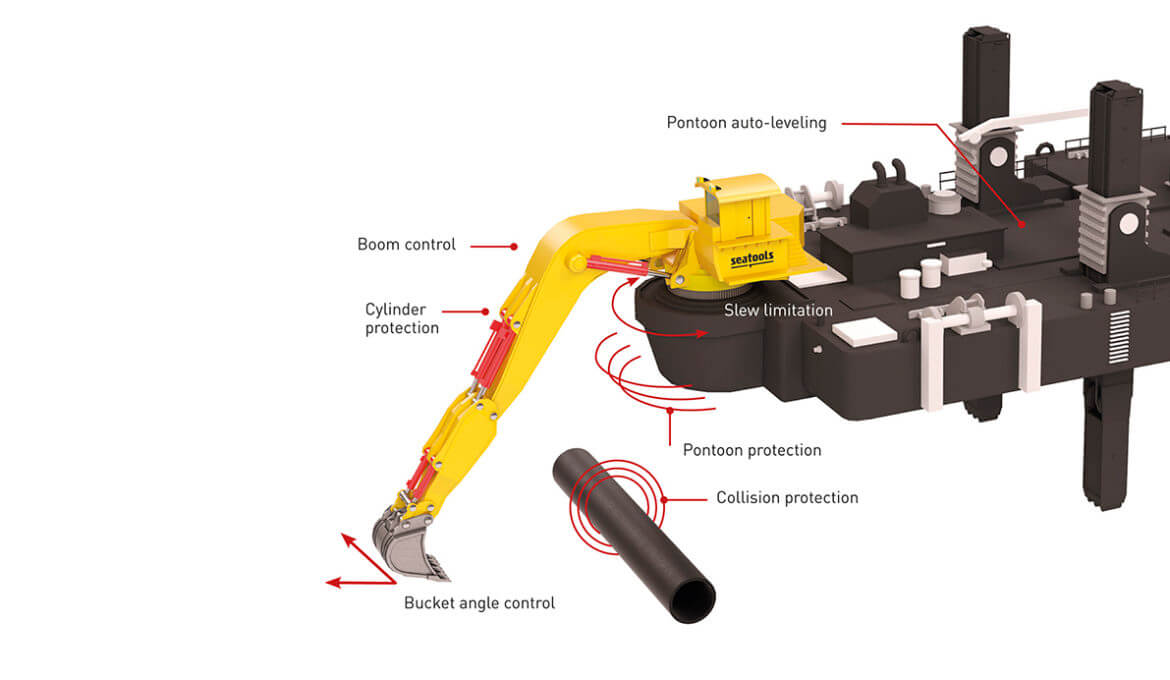

The DipMate Pro, designed to endure the harshest of dredging operations, can be executed with a number of operator assistance functionalities. These enable more efficient (e.g. bucket angle and boom control) and safer (e.g. cylinder and collision protection module) dredging operations. Thanks to the optional operator assistance functionalities, operators of all skill levels are now more accurate and more productive than ever before.

DipMate Pro brochure

Download PDF

- Typical applications

-

- Heavy-duty backhoe and dipper dredgers that aim for maximum dredging efficiency, accuracy, and productivity

- Backhoe dredgers operating in close proximity to existing subsea infrastructure such as pipelines

- Key features

-

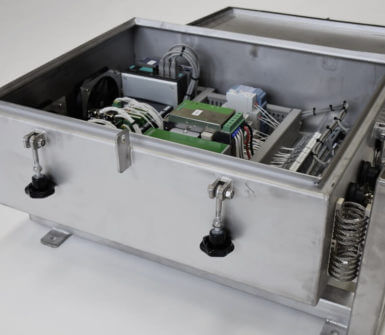

- Ultra-reliable system designed to endure the toughest of conditions

- Maximum dredging performance and safety through excavator automation

- Highly customizable

- Track record

-

- 60+ DipMate® systems active in the field

- Installed among the largest of heavy-duty offshore backhoe dredgers

- Fourth generation at present

The collision protection module of Seatools’ DipMate® enabled Heron Construction to dredge above and alongside live crude oil pipelines without risking pipeline strike. Does your backhoe dredging operation require exceptional safety measures as well?

Key features

-

Ultra-reliable system designed to endure tough conditions

Rugged hardware, combined with highly stable software and robust sensors, facilitate reliable dredging under the toughest of conditions.

-

Maximizes dredging performance and safety through operator assistance

Enabled by high system accuracies and operator assistance functionalities (such as bucket control), operators achieve maximum dredging efficiency, production, and safety.

-

Highly

customizableCombining the DipMate® open system architecture with flexibility on the part of our engineers and a comprehensive list of optional functionalities, Seatools is set to meet any client need and configure an appropriate dredging monitoring and control system for any excavator.

Other features

- Wide range of (terrain) data exchange possibilities

- High update rate for accurate and smooth process visualization

- Online terrain data input

- Highly customizable MMI

- Executed with a range of safety notifications warnings for safe dredging

- 24/7 support for all systems in the field

- Remote access for effective troubleshooting

- Ergonomic operator screen featuring high brightness

Multimedia

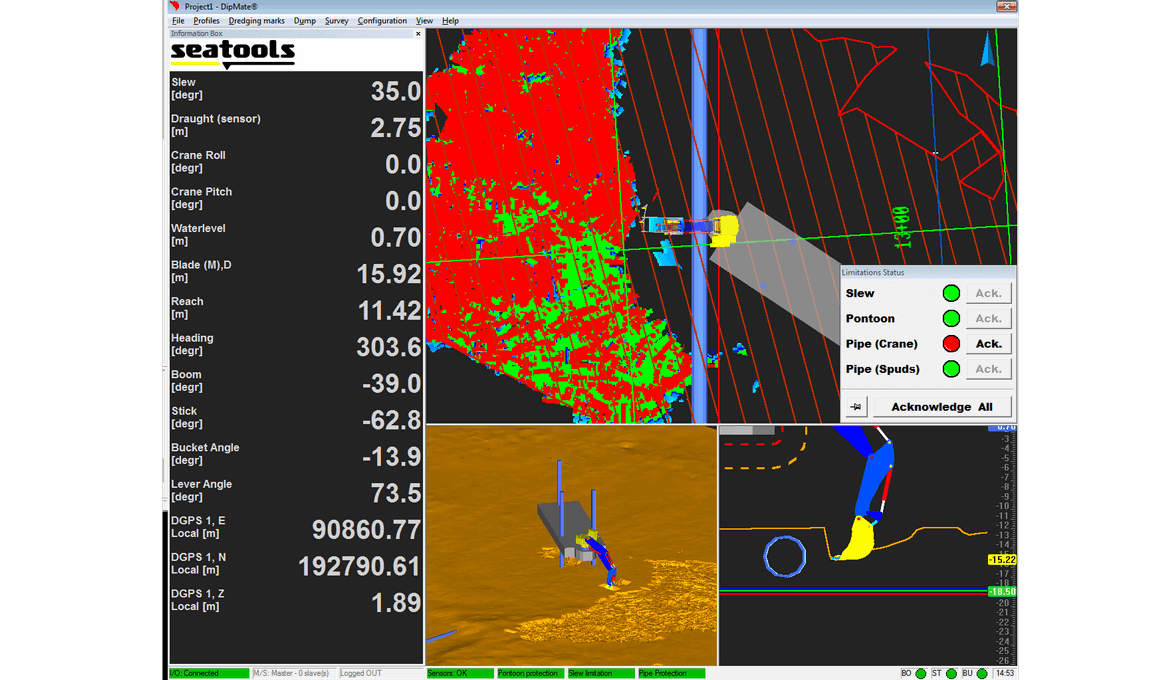

Intervention and operator assistance modules can provide value in multiple ways. The collision protection module, for example, is an intervention module that enables safe and productive backhoe dredging near high-risk objects such as buried live pipelines.

The collision protection module facilitates safe backhoe dredging near live pipelines. When this module is enabled, the operator can set a restricted area (e.g. the pipeline’s location) that ensures the backhoe dredger is slowed down and eventually stopped if it approaches this area.

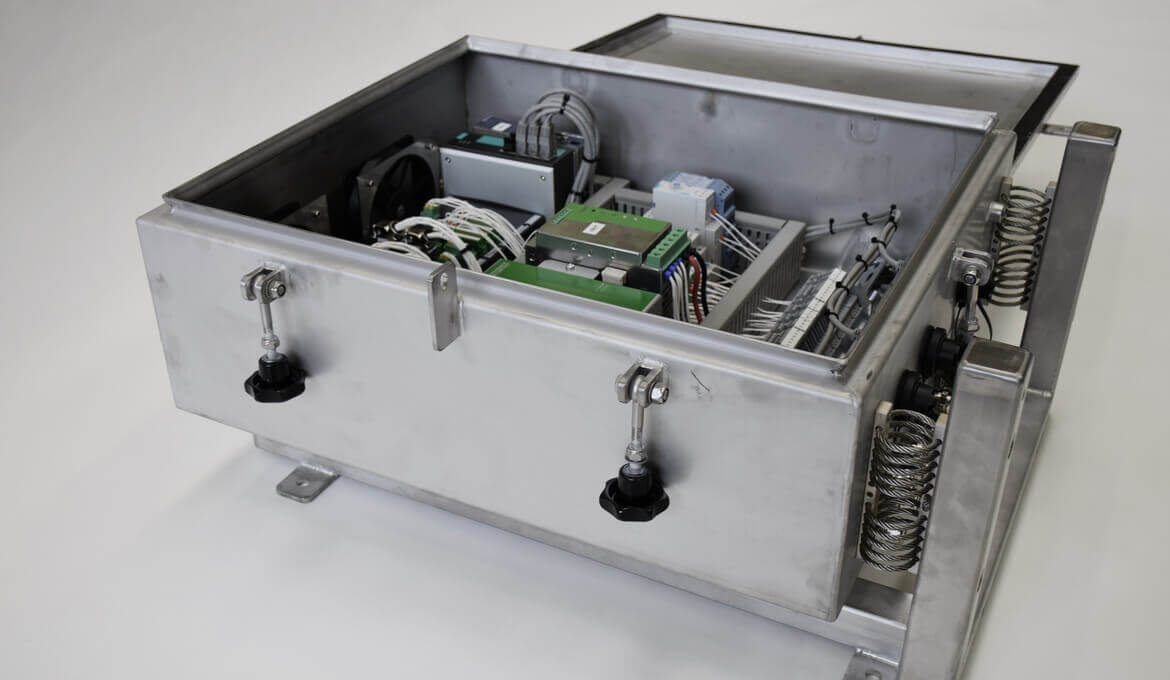

Equipped with shock absorbers to withstand severe shocks and vibrations commonplace during rock and heavy clay excavation.

Related systems

DipMate® Essential – Backhoe dredging monitoring system

Contact

WOULD YOU LIKE TO DISCUSS YOUR PROJECT WITH OUR EXPERTS?

CONTACT FORM

OTHER CHANNELS

- General

- +31 (0) 186 68 00 00

- info@seatools.com

- Sales

- +31 (0) 186 68 00 00

- sales@seatools.com

- Service (outside office hours, emergency only)

- +31 (0)186 65 00 75