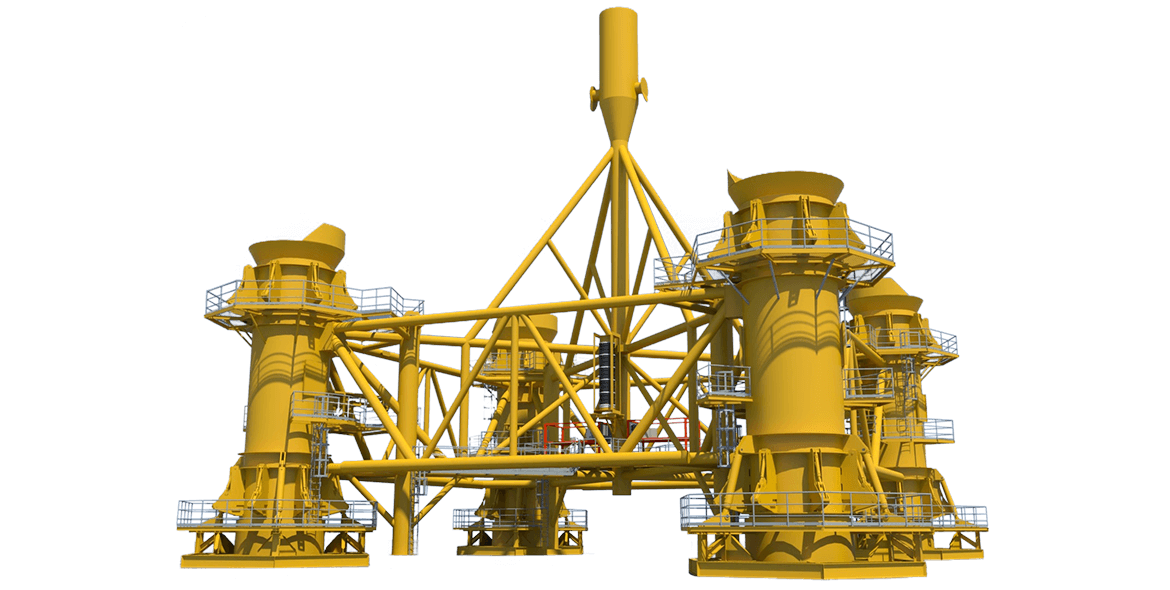

Pre-piling template– PIF

Piling template equipment for productive and accurate offshore piling operations

Overview

Full insight and control for highly accurate and simultaneously efficient offshore pile installation operations

In order to have full insight and control during the offshore piling operations that were part of the construction of a large OWF, Seaway Heavy Lifting contracted Seatools for the design and delivery of a piling template instrumentation and control system. Not only did the severe vibrations and shock loads that occur during piling operations pose technical challenges – the deadline too, made the project extremely challenging.

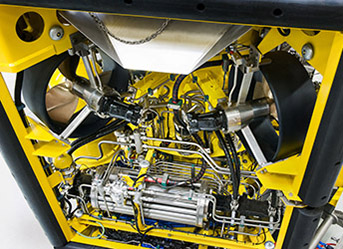

Seatools’ background in the delivery of custom-made dredging instrumentation proved highly valuable for this project. In addition to our extensive range of highly accurate and rugged subsea sensors, Seatools has extensive experience in the design of monitoring and control equipment for operations in vibration- and shock load-rich environments. All of which has contributed to the design of reliable equipment for uninterrupted piling operations. Seatools’ ability to innovate under high time pressure further enabled the development of multiple dedicated monitoring systems. These systems monitored and controlled the piling process, and allowed Seaway to stay well within the limits of the prescribed pile installation tolerances. The full scope of the project was completed within the set delivery time of five months.

- Project scope

-

- Pile template instrumentation and control system

- Hydraulic and mechanical system for template leveling and pile positioning

- Delivery date

-

- March, 2017

- Client

-

A proven subsea technology toolbox, all disciplines under one roof, and a strongly innovative capacity –our approach to realize highly reliable and effective offshore installation equipment. Want to learn more?

Features & Specifications

-

Facilitates high pile installation accuracies

Enabled by Seatools’ proven subsea sensor range, the template includes various dedicated real-time monitoring systems. These highly precise systems, in combination with accurately controlled systems for pile positioning and template leveling, ensure our client stays well within the prescribed pile installation tolerances – while maintaining installation speeds.

-

Highly reliable

designBoth the monitoring and control equipment as well as the hydraulic and mechanical systems for template leveling and pile positioning feature a high level of redundancy and are executed with a solid backup strategy. The architecture of the systems is based on a thorough FMEA analysis, performed in close cooperation with our client.

-

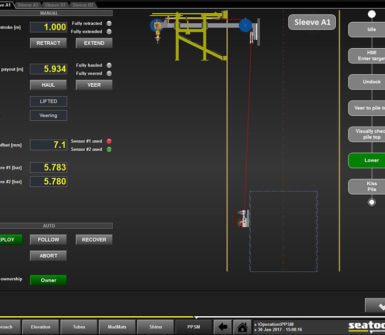

Full insight and control over installation operations

The integrated monitoring and control systems allow for accurate, real-time monitoring of every step of the pile installation process.

SPECIFICATIONS

- Weight Approx. 650 MT

- Dimension (l x b x h) 32 x 32 x 24 m

- Pile diameter 2.2 m

Marcel Remijn, Project Manager at Seaway Heavy Lifting: “We are very pleased with the technical solutions Seatools have provided to our Pile Installation Frame. Working together with Seatools has been an absolute pleasure.”

Multimedia

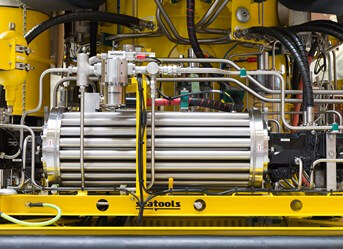

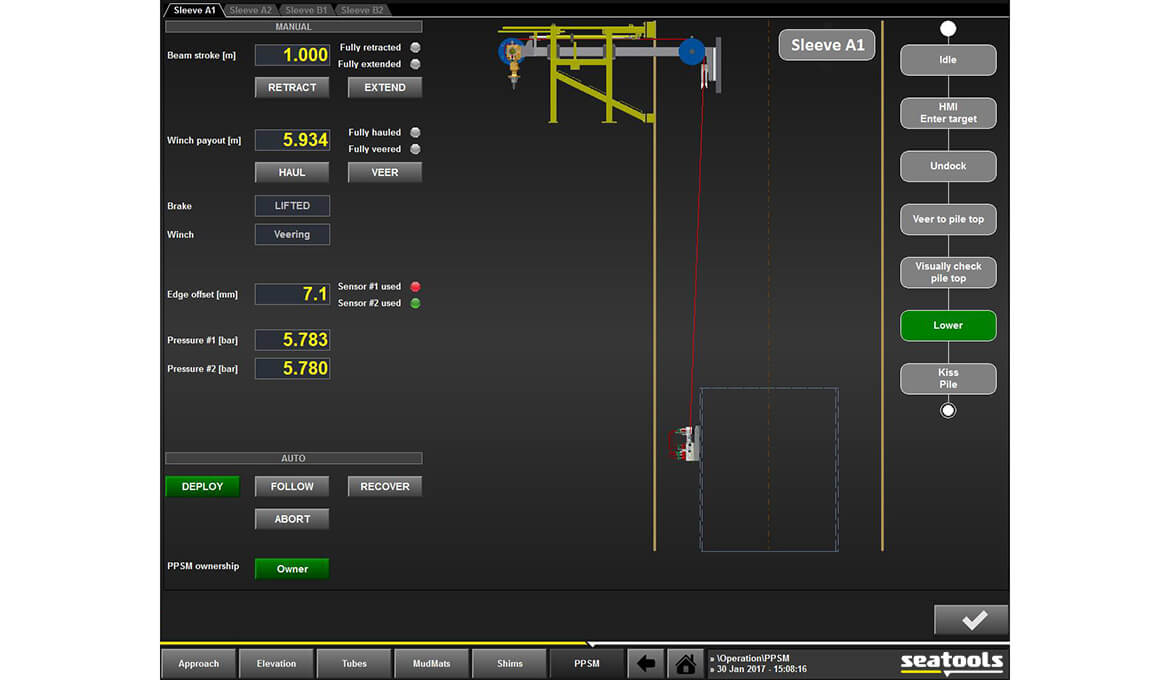

To ensure that the prescribed pile stickup height tolerances were met, a highly accurate and automated Post Pile Stickup Measurement (PPSM) system was developed. During the measurement process, a measurement head is lowered into the sleeve until below the pile edge. The measurement head, consisting of proximity and pressure sensors, is subsequently raised until the proximity sensors detect the pile edge. All the while, pressure sensors accurately measure absolute pressure, on the basis of which pile stick-up height can be determined with a very high level of accuracy.

Contact

WOULD YOU LIKE TO DISCUSS YOUR PROJECT WITH OUR EXPERTS?

CONTACT FORM

OTHER CHANNELS

- General

- +31 (0) 186 68 00 00

- info@seatools.com

- Sales

- +31 (0) 186 68 00 00

- sales@seatools.com

- Service (outside office hours, emergency only)

- +31 (0)186 65 00 75