Subsea pressure compensation and subsea storage

Reliable subsea storage of liquids and pressurization of hydraulic systems

Overview

From basic ROV pressure compensators to large-volume, permanently subsea-situated liquid storage solutions

Seatools houses a large knowledge base in the field of subsea pressure compensation and subsea storage of liquids. This knowledge we acquired by not just selling compensators, but also incorporating them in all of our own projects. This means our underwater pressure compensator and storage designs contain more than 15 years of experience and knowledge gained from internal design reviews and field feedback.

Based on our knowledge base, we developed a high-quality standardized subsea compensator range over time, and provide appropriate pressure compensators for virtually every application. However, we are also able to design and build custom-made subsea pressure compensators and subsea fluid reservoirs for any specific application and technical requirement.

- Expertise

-

- Subsea pressure compensation and compensators

- Subsea Chemical Storage Systems (SCSS)

- Subsea hydraulic systems

- Value creation

-

- An offering that extends beyond compensators and reservoirs

- A solution for every application

- High-quality solutions

- Track record

-

- Delivered numerous subsea compensators and reservoirs

- Delivered subsea compensators with an MTTF of more than 20 years

- Development of permanently situated liquid storage systems

We advise our clients in the selection, installation, and use of our compensators and storage systems. We do so, taking into account pressure and temperature ranges, filling levels, entrapped air, fluid behaviors, and other factors. Learn more?

SCOPE

- Feasibility and conceptual design

- Standardized subsea compensators

- Custom compensators and fluid reservoirs

- Subsea compensator maintenance and repair

Pursuing optimal subsea pressurization and storage solutions

Seatools is capable of and experienced in the performance of (conceptual design) studies to analyze and develop highly specific subsea pressure compensators and subsea liquid storage solutions. This type of studies is typically applied to highly distinct applications, such as subsea chemical storage systems (SCSS) for subsea production facilities. Example subjects include FMECAs, refilling strategies, subsea hydraulic leakage detection, fluid barrier options, interfaces, instrumentation, and controls.

A range of field-proven subsea compensators

Our standardized subsea compensator series are field proven, highly reliable compensators that can be applied to a wide range of subsea applications. All our designs are based on numerous years of field experience gained from the compensators installed on our fall pipe ROVs, which operate under harsh conditions. Our compensators come with a wide variety of possible configurations and options.

Subsea compensators and subsea fluid reservoirs that meet your specifications

Seatools has a strong track record in the design and delivery of custom-made subsea compensators and subsea fluid storage systems. Our made-to-order compensators and fluid storage systems can be designed in accordance with any specification, with variations in required pressure-volume characteristics, mechanical load, temperature levels, types of fluids, required redundancy, and quality standards.

Maintain safe pressure levels throughout your subsea hydraulic system

We perform maintenance on and repair self-manufactured as well as third-party subsea hydraulic compensators and fluid storage systems. In addition to compensators and reservoirs, we also handle subsea hydraulic systems.

HOW WE CREATE VALUE

-

An offering beyond compensators and fluid reservoirs

Not only do we deliver subsea pressure compensators and fluid reservoirs – we also supply related hydraulic components and systems such as subsea HPUs, hydraulic filters, and valve boxes. Beyond this offering, we provide complete hydraulic systems that including all related systems such as mechanics, software, electronics, and controls. In order to guarantee first-time-right delivery when a system is commissioned, we also simulate electro-hydraulic systems from front to back.

-

A solution for every application

Thanks to four different compensator ranges, Seatools can provide subsea pressure compensation for nearly every application. In case our standard compensators do not meet your requirements, we design and deliver custom-made compensators and fluid storage systems, which are optimized for your needs.

-

High-quality solutions

During the past 15 years, our compensators have been used across the board. The feedback we received from our clients has resulted in subsea compensators of the highest quality level.

Standardized compensator and reservoir series

4 different field proven series

- Basic series

- Advanced series

- Ultralong lifetime series

- Subsea liquid storage series

Cost-effective compensator of a light-weight design

A range of cost-effective underwater pressure compensators featuring a light-weight design and volumes ranging from 0.6 to 6 liters. Because mass constitutes an important criterion in the construction of an ROV, our light-weight basic series compensators are a perfect match for ROV applications.

Largely customizable high-end subsea compensator series

High-end subsea hydraulic compensators with compensation volumes of 6 and 15 liters. Time-proven, highly reliable, and solid designs that facilitate relatively high overpressures. Largely customizable, with options for hydraulic connections, electric connections, level measurement, and more.

Compensator series for permanent subsea applications

Hydraulic compensators for (semi-)permanent subsea applications, such as a control fluid reservoir for subsea production systems or subsea mining equipment. Thanks to their ingenious design, a minimum of moving parts is exposed to sea water, which results in a compensator lifetime of over 20 years. Compensator capacities range from 0.7 to 250 litres.

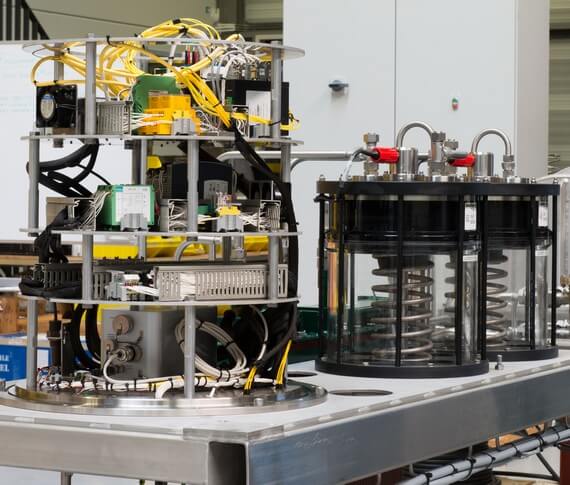

Subsea storage of liquids and pressurization of large-volume hydraulic systems

This subsea storage unit is specifically designed for longterm storage of hydraulic fluids and compensation of large-volume subsea hydraulic systems. Example applications include:

• Control fluid storage open-loop PCS

• Subsea chemical storage

• Subsea transformer and VSD pressure compensation

• Volume compensation large volume actuators

Please contact our sales department for more information.

Related technology

Subsea Chemical Storage System

Seatools’ Subsea Chemical Storage System (SCSS) facilitates safe and long-term subsea storage of commonly used production chemicals.

Seatools is a one-stop shop for subsea hydraulics: in addition to subsea compensators and reservoirs as well as various other subsea hydraulic components, we provide complete subsea hydraulic systems.

TRACK RECORD

A trustworthy track record

- Date:

- January 2018

- Project duration:

- 4 months

- Client:

-

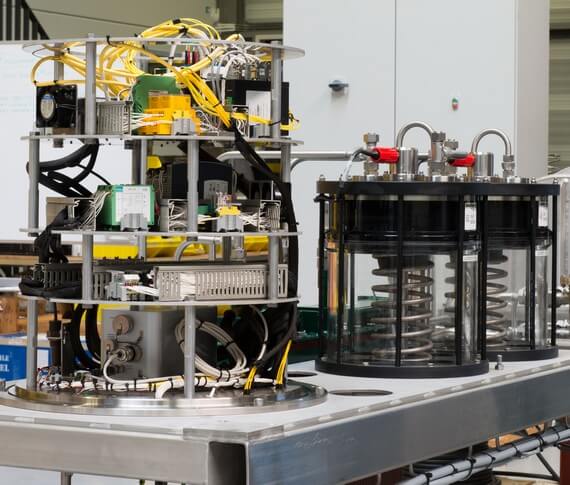

250-liter Ultralong lifetime pressure compensators for heavy-duty 1.7 MW submersible electric motors

Our client Bakker Sliedrecht required subsea compensators capable of providing compensation for 1.7 MW submersible electric motors installed on a new hopper dredger.

Due to the harsh conditions in which these units will operate, the Ultralong lifetime compensator design was selected. Also, the application demanded a low pressure gradient, which had to be met within narrow tolerances. Detailed modelling, testing, and subsequent analysis showed that the compensator met all stringent pressure tolerances well within the prescribed 0.05 bar.

- Date:

- March 2017

- Project duration:

- 5 months

-

1100-liter subsea hydraulic reservoir for large-volume subsea hydraulic system

In order to have full insight and control during the offshore piling operations, Seaway Heavy Lifting contracted Seatools for the design and delivery of a piling template instrumentation and control system.

The scope of supply included the complete subsea hydraulic system, which consisted of a large number of hydraulic actuators for template leveling and pile positioning. As existing hydraulic compensator designs were unable to store the significant differential (oil) volumes caused by a large actuation volume, a dedicated 1100-liter subsea hydraulic reservoir was designed and implemented by Seatools.

- Date:

- October 2013

- Project duration:

- 9 months

- Client:

-

Development of a pressure compensation technology with 20-year uninterrupted seafloor performance

Our client Siemens AS required a subsea compensator capable of delivering uninterrupted seafloor performance for more than 20 years. A design criterion that demanded a different design approach.

Following a conscientious design, manufacturing, and assembly process, the compensator was subjected to extensive in-house testing and qualification programs to guarantee the uninterrupted long-term performance of this mission-critical system.

- Date:

- October

- Project duration:

- 6 months

- Client:

-

Design and analysis of long-term subsea reservoir

On behalf of Statoil, Seatools performed an engineering study of a subsea storage system for control fluids. Next to a conceptual design, the study included an analysis of the required controls and instrumentation, refilling strategies, and OPEX and CAPEX estimations.

Using several different assessment and design methodologies, we were able to develop a powerful concept for the subsea storage of control fluids best suited for this particular application.

- Date:

- April 2016

- Project duration:

- 12 months

- Client:

-

ROV executed with multiple advanced series compensators

The ROV 7 fall pipe ROV, built for Van Oord, integrates all of Seatools’ knowledge and capabilities in the field of fall pipe ROVs, and represents the state of the art regarding custom-built ROVs.

In order to pressurize the ROV’s hydraulic system, multiple advanced series compensators were incorporated. In order to prevent environmental damage from oil spillage caused by peak pressures, the compensators were executed with oil discharge collectors.

- Date:

- June 2002

- Project duration:

- 13 months

- Client:

-

Heavy-duty compensators for deep-water dredging technology subjected to harsh operating conditions

A new dredging method was required to excavate in challenging soil conditions at a water depth of 150 meters. To this purpose, the Grab Excavation System (GES) was developed.

Advanced compensators were used to pressurize the hydraulic system. In addition, two 250-liter heavy-duty compensators were applied to compensate for oil volume changes caused by hydraulic cylinder actuation. The compensators were subjected to extensive (dynamic) performance testing.

- Date:

- September 2007

- Project duration:

- 9 months

- Client:

-

Hydraulic pressurization of subsea monitoring system

For the accurate positioning of submerged tunnel elements, Seatools developed a highly accurate subsea measurement system: the Tunnel Segment Measurement System (TSMS).

For the pressurization of the hydraulic systems incorporated in each of the measurement units, light-weight basic series hydraulic compensators were applied. This met the requirement of minimizing system weight, as the TSMS was to be installed by divers.

- Date:

- December 2011

- Project duration:

- 11 months

- Client:

-

Subsea pressure compensation for revolutionary ROV technology

The Rockpiper is a highly automated fall pipe ROV with integrated survey ROV. The survey ROV features full DP functionalities, and can dock and undock fully automatically in order to perform direct post-process surveys, which results in major cost savings.

Both the main ROV and the survey ROV feature electro-hydraulic drive configurations. To pressurize their hydraulic systems, the ROVs contain a mixture of multiple basic and advanced series compensators.

- Date:

- August 2006

- Project duration:

- 7 months

- Client:

-

Hydraulic pressure compensation for a highly effective subsea pipeline trencher

The Arthopod 600 is a subsea pipeline trencher suitable for pre- and post-lay subsea trenching. Seatools developed an innovative subsea pipeline trenching technique that creates large trenches in hard soils in a very efficient manner.

In order to pressurize the Arthopod’s hydraulic system and act as reservoir for oil volume changes caused by hydraulic cylinder actuation, a mix of advanced and heavy-duty compensators were applied.

- Date:

- August 2001

- Project duration:

- 5 months

- Client:

-

Subsea pressure compensation for a compact and easy-to-transfer FPROV system

This highly compact fall pipe ROV was completed in 2009 for Jan de Nul. The system’s compact design facilitates easy transportation and use on various of our clients’ vessels. This ROV is capable of fully automated dynamic positioning.

In order to pressurize the hydraulic system and cope with the system’s strong temperature fluctuations, the ROV is executed with basic and advanced series underwater pressure compensators.

RELATED NEWS

Seatools completes delivery of high-end pressure compensators for Bakker Sliedrecht

10 January, 2018

On behalf of its client Bakker Sliedrecht, Seatools completed the development, manufacturing, and testing of two 250-liter subsea pressure compensators. The compensators will be applied to 1.7 MW submersible motors.

Seatools introduces subsea storage technology

January 31th, 2017

Seatools completed an R&D program on a subsea liquid storage technology. During the program – a continuation of an earlier engineering study performed on behalf of Statoil Petroleum AS – the storage technology successfully passed a full product qualification test program.

Seatools introduces Advanced series subsea compensators

20 December, 2016

The new subsea compensator range, based on the preceding Hyco range, incorporates more than 15 years of experience and field feedback, and delivers serious improvements in robustness, durability, and standardization.

CONTACT

Would you like to discuss your project with our experts?

CONTACT FORM

OTHER CHANNELS

- General

- +31 (0) 186 68 00 00

- info@seatools.com

- Sales

- +31 (0) 186 68 00 00

- sales@seatools.com

- Service (outside office hours, emergency only)

- +31 (0)186 65 00 75