SUBSEACLEANING

Effective cleaning solutions that facilitate sustained performance and minimize downtime of your primary operations

Overview

SEATOOLS DESIGNS, MANUFACTURES, AND DELIVERS CUSTOM-MADE SUBSEA CLEANING SOLUTIONS

The design of effective remote subsea cleaning solutions is characterized by a diffuse set of stringent design criteria. In addition to essentials like equipment reliability and (cleaning) efficiency, remote cleaning solutions should eliminate the risk of damaging a structure or coating, demonstrate fail-safe behavior at remote locations, and have the ability to cope with obstructions.

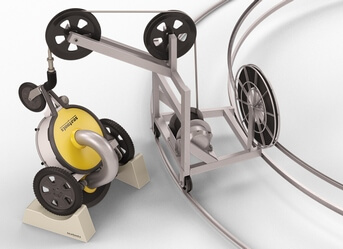

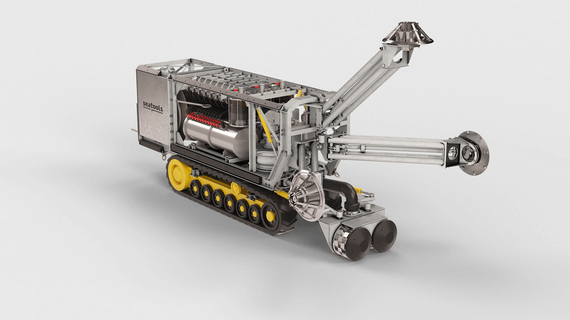

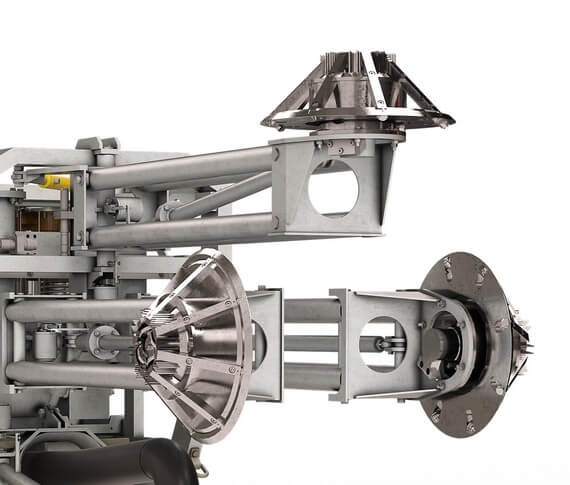

In order to meet these criteria, an extensive knowledge base and set of capabilities are required, that includes knowledge of cleaning principles, advanced control engineering, and the design of autonomous vehicles. Because Seatools houses the required knowledge and capabilities, and has a strong innovative capacity, we can design and deliver effective remote cleaning solutions that tackle a broad variety of underwater cleaning challenges. The ROCM underwater cleaning robot is a case in point. Here, we effectively combined the above-mentioned fields of knowledge and delivered a successful remote cleaning solution for a complex cleaning assignment.

- EXPERTISE

-

- Expertise on subsea cleaning principles (jetting, brushing, scraping)

- Expertise on design and manufacturing of ROVs and subsea tools

- Expertise on the collection and processing of marine fouling

- Expertise in the cleaning of water intakes at power and desalination plants

- VALUE CREATION

-

- Innovative and bespoke subsea cleaning solutions

- Partnership approach

- Advanced control systems for safe and productive cleaning operations

- TRACK RECORD

-

- Innovative designs for highly specific subsea (infra)structure cleaning

- Design of remote underwater cleaning robots that prevent downtime

The ROCM removed a 25-centimeter-thick layer of marine growth in a 400-meter-long power plant cooling water intake in as little as 80 hours. How can we maximize your cleaning operations?

Scope

- FEASIBILITY, FMEA, AND CONCEPT STUDIES

- COMPLETE CLEANING TOOLS AND EQUIPMENT SOLUTIONS

YOU PROVIDE THE CASE AND REQUIREMENTS, WE SEEK OUT A SOLUTION

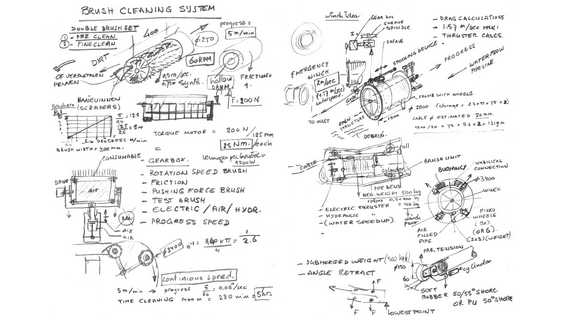

We perform feasibility and conceptual design studies to investigate potential underwater cleaning solutions. During these studies, we take into account factors such as the type of encountered marine growth, required cleaning capacity, inspection requirements, (potential) obstructions, equipment failure cases, propulsion possibilities, fouling capture, and possible deviations from “as-built” drawings. Usually, these studies are conducted in collaboration with (power or desalination) plant owners or maintenance contractors. In such a collaboration, Seatools contributes its expertise in underwater cleaning equipment, while the partner manages or handles complementary operations and equipment, including launch and recovery operations.

DELIVERY OF TURN-KEY, BESPOKE SUBSEA CLEANING EQUIPMENT SOLUTIONS

Thanks to our multidisciplinary engineering approach, we do not only deliver conceptual designs, but also realize these concepts and deliver full-fledged, turn-key equipment solutions. All our equipment solutions are factory tested, and provide training to our clients’ operators.

HOW WE CREATE VALUE

-

INNOVATIVE AND BESPOKE

SUBSEA CLEANING SOLUTIONS

Only custom-made solutions achieve the best possible cleaning performance. Our innovative capacity and our expertise and knowledge of underwater cleaning principles, control engineering, and autonomous vehicle designs, culminate in design equipment solutions that deliver an exact match with the performance criteria of our customers.

-

PARTNERSHIP APPROACH

Seatools acts as a partner to plant owners, including those who own near-shore power plants or desalination plants, as well as contractors engaged in maintenance work. Through collaboration, Seatools leverages its expertise in industrial underwater cleaning equipment in tandem with the operational knowledge of these partners, enabling the achievement of optimal results.

-

ADVANCED CONTROL SYSTEMS FOR SAFE

AND PRODUCTIVE CLEANING OPERATIONS

Our advanced control engineering capabilities facilitate controlled remote cleaning operations. Force control, for example, eliminates the risk of damaging the (coating) surface, while optimizing cleaning progress.

What do you need to get cleaned to guarantee the uninterrupted performance of your primary operations? Our experts gladly discuss your requirements and point out potential solutions for your project.

RELATED SYSTEMS

Remotely Operated Mort Collector

The ROMoC is a highly automated mort collection system designed for dead fish collection in large-scale offshore fish farms.

Pile Dredge Tool – PDT

A simple and versatile pile dredge tool that facilitates effective pile dredging operations and marine growth removal.

TRACK RECORD

- Project duration:

- 6 months

Effective power plant cooling water intake cleaning

As part of a major overhaul project at Hong Kong’s Black Point Power Plant, the cooling water intakes were scheduled to be cleaned of a 25-centimeter-thick layer of biofouling. The customer’s main concern – safety and a minimum of downtime – required the design of a dedicated underwater cleaning machine.

Seatools developed a dedicated Remotely Operated Cleaning Machine (ROCM) that proved very successful: the ROCM cleaned a 400-meter-long tunnel in as little as 80 hours.

- Project duration:

- 4 months

- Client:

-

Control system for remote hull cleaning

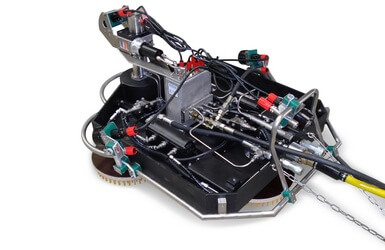

Hydrex successfully developed a diver-operated hull cleaning machine, but wanted to advance the development of the machine by incorporating a large degree of automation, and eliminate the need for a diver.

Thanks to its advanced control engineering capabilities, Seatools was asked to step in, and successfully developed and integrated a remote control system. The system facilitated position control, and controlled the cleaning process without requiring a diver.

- Project duration:

- 4 months

- Client:

-

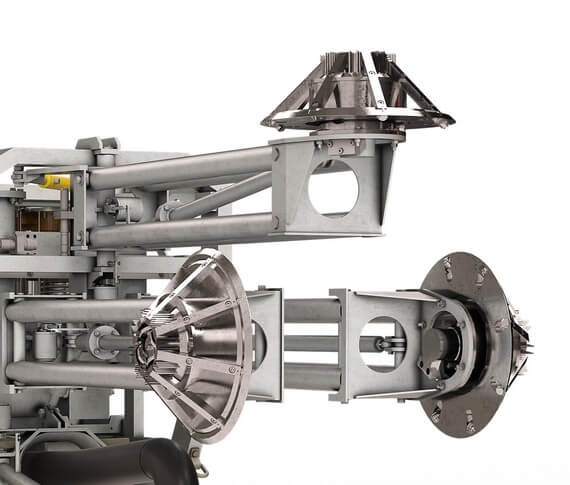

Power plant intake cleaning without downtime

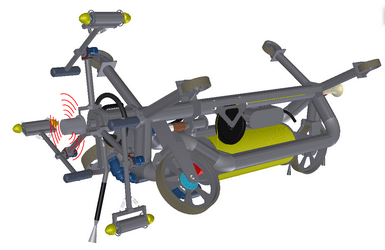

The cooling water intakes of a German power plant suffered from biofouling. Seatools was approached to develop a concept for the remote cleaning of circular intakes while avoiding power plant downtime.

The project resulted in a feasible conceptual design in which all related operational aspects were taken into account. The design was capable of traversing the circular cooling water intakes, while cleaning their surfaces without causing any downtime.

Related news

Seatools introduces mort collector for offshore fish farms

January 11th, 2017

Seatools completed a feasibility and conceptual design study on a Remotely Operated Mort Collector (ROMoC). The study resulted in a highly automated system capable of effectively collecting dead fish in large-scale offshore fish farms.

Seatools introduces ‘elegantly simple’ Pile Dredge Tool

20 April, 2016

Seatools introduces ‘elegantly simple’ Pile Dredge Tool. This pile cleaning and dredging system is capable of removing soil plugs and cleaning of pre-piled jackets, such as commonly found in the offshore wind industry.

Contact

Would you like to discuss your project with our experts?

CONTACT FORM

OTHER CHANNELS

- General

- +31 (0) 186 68 00 00

- info@seatools.com

- Sales

- +31 (0) 186 68 00 00

- sales@seatools.com

- Service (outside office hours, emergency only)

- +31 (0)186 65 00 75