Ultralong lifetime compensators

Endurance by design

Overview

Designed for long-life operation, proven in industrial subsea applications worldwide

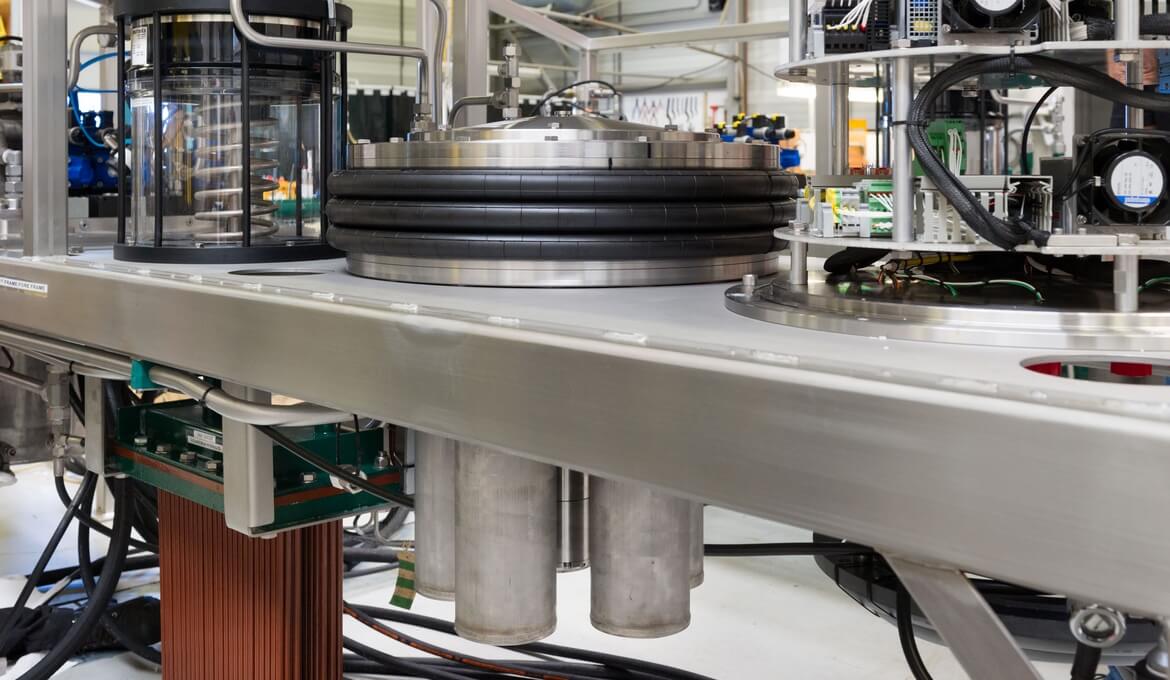

The Ultralong Lifetime Series compensators are specifically designed to provide reliable pressure compensation for subsea and submerged equipment operating under extreme and long-term conditions. These compensators serve (semi-)permanent subsea installations where durability and reliability are critical. With a design life exceeding 20 years, they are ideally suited for the most demanding applications such as subsea mining systems, submerged dredging equipment, and subsea production facilities including HPUs, power transformers, and other critical subsea systems.

Achieving such an extended design life requires an unconventional mechanical design that minimizes the exposure of moving components to the marine environment. Every detail—from corrosion protection measures to the long-term material behavior of each component—has been carefully considered during development. The design was successfully qualified in accordance with API 17N standards and has since proven itself in the field as a robust and reliable compensator solution, trusted and applied by leading offshore contractors and OEMs worldwide.

- Typical applications

-

- Subsea mining equipment

- Subsea production equipment such as SCM SHPUs and switch gear

- Submersible dredge motor pump compensation

- Key features

-

- Durable design: MTTF of more than 20 years

- Designed, tested, and qualified at the highest industry quality standards

- High degree of customization

- Applied to

-

- SHPU for SCM

- 1.7 MW subsea dredge pump motors

- Subsea mining vehicles

To ensure that the right size and type of compensator is selected, we advise our clients during the selection process. We do so, taking temperature ranges, pressure ranges, filling levels, entrapped air, fluid behaviors, and other factors into account.

Key Features

-

Durable design: MTTF of more than 20 years

The Ultralong Lifetime Series features a robust mechanical design that minimizes the exposure of moving components to the marine environment. This ensures long-term integrity and consistent performance in continuous subsea service.

-

Developed at the highest industry quality standards

With a design life exceeding 20 years under typical subsea conditions, these compensators deliver exceptional longevity. Their reliability has been validated through extensive testing and qualification in accordance with API 17N.

-

Proven field

performanceExtensive operational experience across a wide range of subsea applications has demonstrated the Ultralong Lifetime Series’ ability to maintain stable performance throughout its service life.

Optional

- Level measurement (various grades)

- Advanced testing programs

- Custom sizing

- Surface treatment

- Custom dP / dV curves

- Protection cover

Ultralong lifetime compensator range

- Compensation volume (liters)

- Pressure min / max (bar)

- Depth rating (msw)

- Weight (kg)

- Compensation volume (USG)

- Pressure min / max (PSI)

- Depth rating (ft)

- Weight (lbs)

Next to our standardized series, Seatools offers custom-made hydraulic compensators that are tailored to your specifications. Please contact our sales engineers to discuss your requirements.

Multimedia

Normal factory testing procedures include internal pressure testing, leakage testing, and functional testing. In addition, we also offer more extensive factory testing and

qualification programs including external pressure testing, fatigue and life cycle testing, temperature range testing, and contamination testing. In addition, the compensator can be delivered flushed to a pre-defined cleanliness level class

Contact

Would you like to discuss your project with our experts?

CONTACT FORM

OTHER CHANNELS

- General

- +31 (0) 186 68 00 00

- info@seatools.com

- Sales

- +31 (0) 186 68 00 00

- sales@seatools.com

- Service (outside office hours, emergency only)

- +31 (0)186 65 00 75

Alternative compensator series

Basic Series

A range of cost-effective underwater pressure compensators that feature a light-weight design and volumes ranging from 0.6 to 6 litres. Because mass constitutes an important criterion in the construction of ROVs, our light-weight basic series compensators are a perfect match for ROV applications.

Advanced compensators

High-end subsea hydraulic compensators with compensation volumes ranging from 6 to 15 liters. Time-proven, highly reliable, and solid designs that facilitate relatively high overpressures. Largely customizable, with options for hydraulic connections, electric connections, level measurement, and more.